Opis

Ulivanje pod tlakom je postopek ulivanja kovin, za katerega je značilno siljenje

staljena kovina pod visokim pritiskom v kalupno votlino. Ustvari se votlina plesni

z uporabo dveh kaljenih matric za orodno jeklo in delujte podobno kot brizgalni kalup

med postopkom. Tipični materiali za visokotlačno litje so

zlitine na osnovi aluminija, cinka, magnezija, bakra in kositra. Odvisno od vrste

kovine, ki se vlije, se uporablja vroča ali hladilna naprava. Auwell običajno

zagotavlja storitve kalupov za vlivanje aluminija in cinka z vročimi komorami in

izdelkov.

Ulivanje pod visokim tlakom se lahko izvede v eni ali več votlinah, uporaba enotnih matric ali kombinacija matric je odvisna od zahtev izdelka.

Different type of dies in the die casting process:

-Single cavity to produce one component

-Multiple cavities to produce several identical parts

-Enota umre za izdelavo različnih delov hkrati

-Kombinirana matrica za izdelavo več različnih delov za sklop

Oprema za ulivanje in kovinske matrice predstavljajo velike kapitalske stroške. Tako je še posebej primeren za velike količine majhnih do srednje velikih odlitkov, zato tlačno ulivanje z visokim tlakom proizvede več ulitkov kot drugi postopki ulivanja. Visokotlačno tlačno ulivanje odlikuje izvrstna površinska obdelava (po standardih ulivanja) in natančnost dimenzij.

High pressure die casting is now considered as an industrial procedure,

used to manufacture parts for sale, or as part of machines for any other

commercial or industrial production. The process allows production of accurate

products to the desired size, shape, and thickness with tight tolerances,

making it the most simple yet effective casting process, essential for creating

metal parts with specified details and quality demands.

High pressure die casting is proven as beneficial to products. In this

process, various modifications can be made to the production. Manufacturers

spend less funds and less time in the making of the produced die-cast parts

which are more attractive to the eyes of the buyers.

High pressure die casting can eliminate post-machining and repeated

molding. The process is very economical and finished products made under this

process are accurate and long-lasting.

Visokotlačno tlačno ulivanje je učinkovit, ekonomičen postopek, ki v tujini ponuja vrsto oblik in komponent kot katera koli druga proizvodna tehnika. Deli imajo dolgo življenjsko dobo in so lahko zasnovani tako, da dopolnjujejo vizualno privlačnost okoliškega dela.

Prednosti visokotlačnega tlačnega ulivanja so naslednje:

-Hitra proizvodnja

Visokotlačni tlačni ulitki podpirajo zapletene oblike z natančnejšimi tolerancami v primerjavi z mnogimi drugimi postopki množične proizvodnje. Potrebna je malo ali nič obdelave in pred dodatnim orodjem je mogoče izdelati na tisoče identičnih ulitkov.

-Excellent dimensional accuracy and stability

High pressure die casting

produces parts that are durable with dimensional consistancy while maintaining

close tolerances. They are also heat resistant.

-Strength and weight

High-pressure die casting

parts have considerable high tensile strength at 415mpa. Thin wall castings are

stronger and lighter than those possible with other casting

methods.

-Več tehnik dodelave

High-pressure die-cast

parts can be produced with smooth or textured surfaces, and they are easily

plated or finished with minimum surface preparation.

-Simplified assembly

High pressure die casting

provides integral fastening elements, such as bosses and studs. Holes can be

cored and made to size using tap drills, external threads can otherwise be

cast.

Auwell ponuja različne vrste storitev, da izpolni zahteve strank. Imamo bogate izkušnje pri načrtovanju in izdelavi visokotlačnih orodij za tlačno litje za svetovni trg, zlasti za države EU. Izdelujemo matrice in izdelke iz litine, vključno z obdelavo in površinsko obdelavo, za stranke.

Tehnične specifikacije

-Core Element Material

H13, 1.2344 (X40CRMoV51), 1.2367 (X38CrMoV5-1), H11, 1.2343 (X38CrMoV5-1)

Bolster Material:P20,

1.2312, 1.2738

-Standardne komponente

HASCO, LKM standard ali po meri

-Material za priljubljene izdelke

AL226, AL230, AlSi10Mg,

360,380,383, 413 and A304 K-alloy, ADC12, ADC10, Zamak 3, Zamak 5, ZA-8, ZA-12

and ZA-27 etc.

-Dodelava površine izdelka

Includes but is not

limited to: brush, line polishing, high gross polishing, mirror polishing, sand

blaster, anodizing, zinc-plating, chrome-plating, nickel-plating, powder

coating, silver coating, E-coat, wet paint, silk screening and stenciling etc.

-Največja sila zapiranja obdelave

4.000 ton, delna teža: 5-30.000g

Prednosti

-Rich Experience

Več kot 20 let izkušenj pri razvoju in proizvodnji izdelkov za tlačno litje pod visokim tlakom, zlasti na evropskem in severnoameriškem trgu, z dobrim razumevanjem materialnih, tehničnih in kakovostnih standardov po vsem svetu.

-Fast Turnaround

Na splošno nudimo aquotation v 3 delovnih dneh. Z združitvijo najnovejših proizvodnih tehnologij in naprav lahko Auwell za začetne vzorce v samo 5 tednih zagotovi preproste projekte.

-Comprehensive Solution Provider

Auwell nudi celovite storitve za projekte tlačnega ulivanja pod tlakom, od načrtovanja, izdelave prototipov, razvoja orodij / naprav, vzorčenja, množične proizvodnje ter logistične in poprodajne podpore.

-Toge politike nadzora kakovosti

The most rigorous quality

policy starts from material control, and is followed through to final

pre-shipment inspection. Material certificates include the mill certificate,

3rd party chemical components, and mechanical property reports, as well as RoHS

and REACH reports upon request. Other reports include dimensional reports,

surface treatment thickness, and salt fog test reports, etc. We structure our

processes, creating Flow Charts and Control Plans before production, making

sure all QC processes are in accordance with ISO9001-2015 requirements and

drawing specifications.

-Flexible Payment Term

Za množično proizvodnjo bomo ponudili prilagodljive plačilne pogoje, dobili bomo razumne kreditne pogoje, kupec plača samo, ko je zadovoljen s prejetim izdelkom. Za dolgoročne projekte ponujamo storitve odpoklicnega inventarja za potrebe hitre dostave.

Applications

High pressure die casting products have widely been used in almost all

industrial sectors including:

-Aerospace and defense

-Automotive

-Kmetijski stroji

-Energy

-Elektronika

-Gradnja

-Transportation

-Industrijski

-Consumer Products

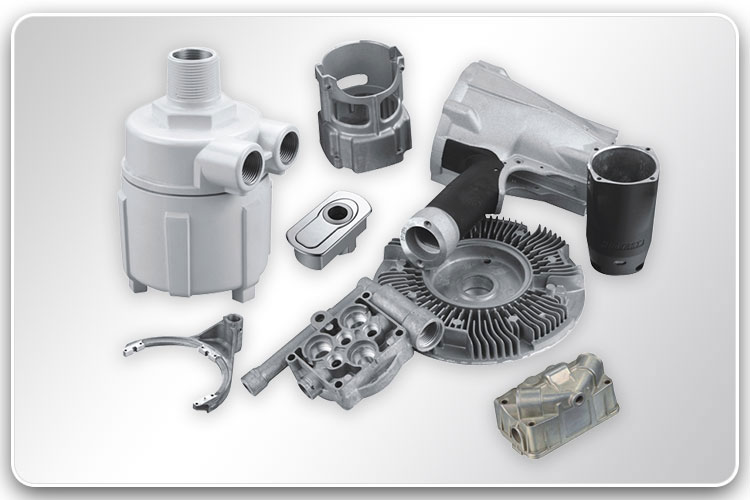

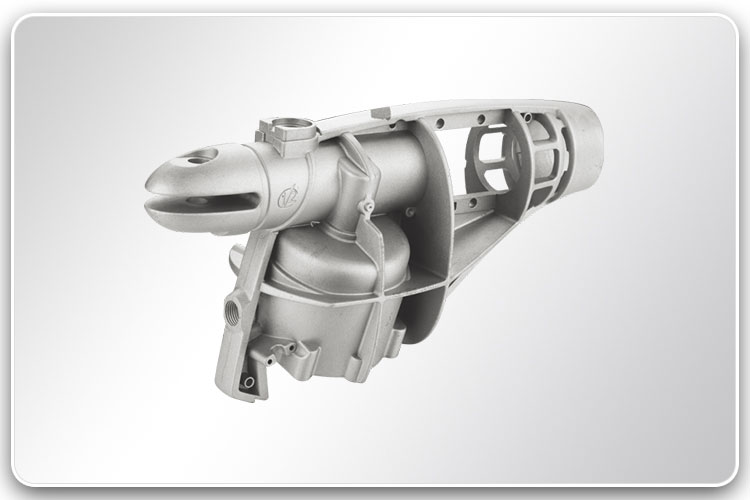

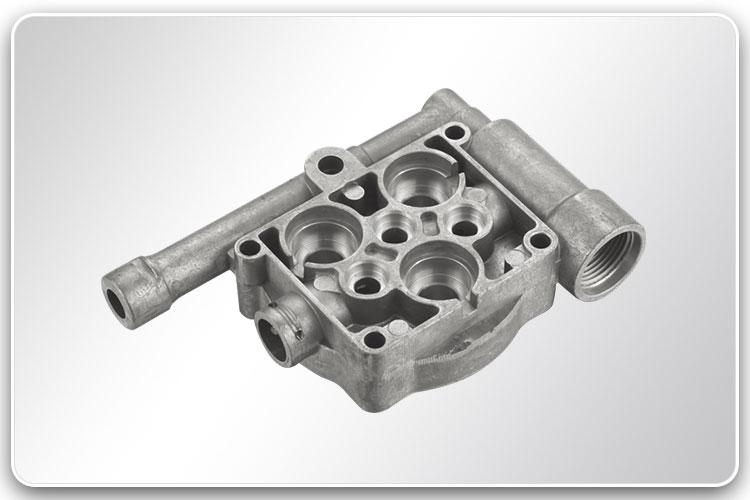

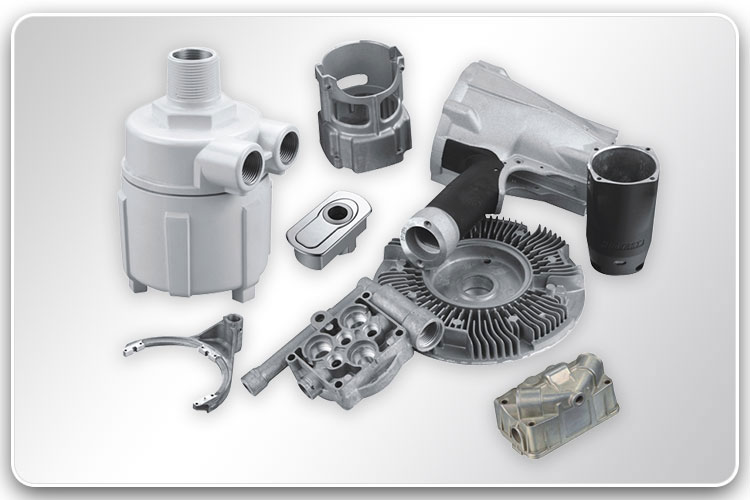

Naslednji katalogi izdelkov za visoko tlačno litje so tisti, ki jih je Auwell izdelal in dobavil našim uglednim strankam po vsem svetu. Za podrobnosti kliknite ustrezne slike. Upoštevajte, da je večina izdelkov namenjena samo predstavitvi.

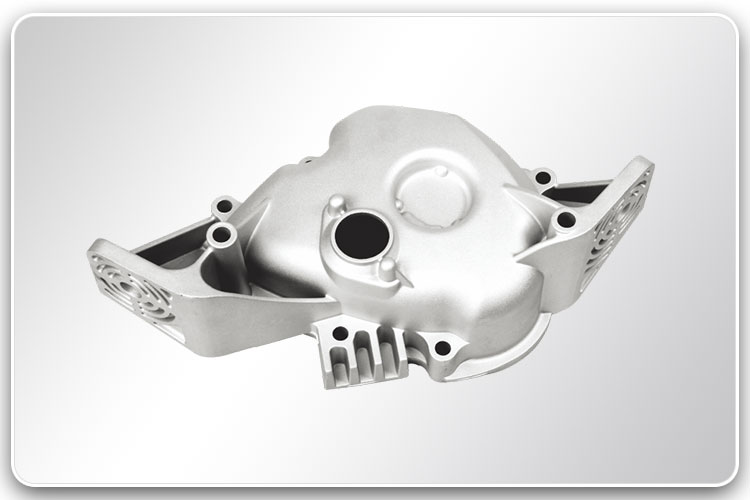

Aluminum Die Casting Automotive Parts

Aluminum Die Casting Automotive Parts

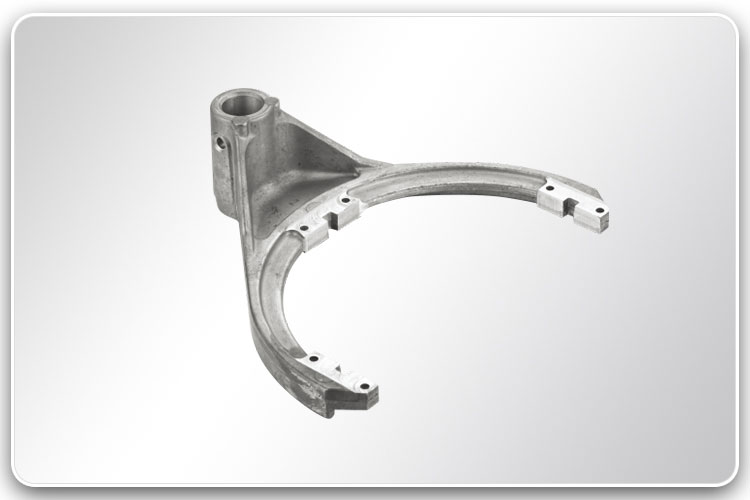

Aluminum Die Casting Industrijski Parts

Aluminum Die Casting Industrijski Parts

High Pressure Die Casting Tooling

High Pressure Die Casting Tooling

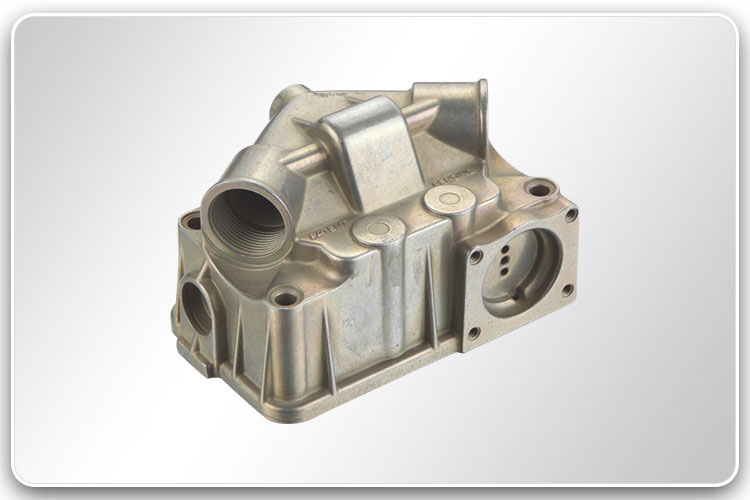

Visokotlačni deli za tlačno litje

Visokotlačni deli za tlačno litje

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик