Description

Oblikovanje gume in silikona je proizvodni postopek, pri katerem se količina neosušene gume ali silikona spremeni v uporaben izdelek.

There are 3 types of Rubber & Silikon molding process:

-Rubber compression molding

Namestitev vnaprej določene količine gumene zmesi neposredno v votlino kalupa in nato stiskanje v obliko votline z zapiranjem obeh strani kalupa.

-Vbrizgavanje gume

In this Rubber &

Silikon molding process the uncured rubber compound is heated to a liquid

state before being injected into a mold. The product is released by opening the

mold and closing it again to receive the next injection.

-Rubber transfer molding

Med tem postopkom oblikovanja iz gume in silikona se nepotrjena guma ali silicijeva zmes položi v del kalupa, ki se imenuje "lonec", preden se skozi odprtino potisne v votlino v obliki želenega izdelka. Ko se kalup strdi, se sprosti končni izdelek.

Auwell material za oblikovanje gume in silikona:

-Nitrile or Buna-N

The most popular and

low-cost solution in Rubber & Silikon molding

-Hydrogenated Nitrile

This is a more expensive

hydrogenated variation of Nitrile polymer, which increases its resistance to

heat, petroleum products, and ozone almost fivefold.

-Etilen-propilen-dien-monomer (EPDM)

Commonly used in rubber

molded products for steam systems, vehicles panel seals, and braking systems

due to its high resistance to brake fluid

-Silikon

Odporen na izpostavljenost visokim in nizkim temperaturam, je zelo prilagodljiv in ima dobro vremensko odpornost.

-Fluorosilikon

Combines the temperature

range advantages of silicone with the resistance to oil, fuel, and solvents

found in fluorocarbons.

-Neopren

As a strong multi-purpose

material, it can be used in a large number of rubber molding solutions. It has

good fire resistant and abrasion properties and is frequently used in the

manufacture of mass transit and transportation equipment

-Naravna guma

Naravni izdelek, proizveden iz lateksa, pridobljenega iz gume

-SBR (stiren butadien)

Eden bolj

stroškovno učinkoviti polimeri, ki se lahko uporabljajo pri oblikovanju gume in so pogosto

uporabljajo pri proizvodnji pnevmatik, membran, tesnil in tesnil ter mase

proizvodnja drugih gumijastih delov

-Fluorocarbon

Ta razmeroma draga gumena zmes združuje širok spekter kemijske odpornosti in lastnosti pri visokih temperaturah.

-Butyl

Has a high resistance to

gas permeability. This makes it the ideal solution in the production of seals

for high-pressure gas and vacuum systems

-Uretan

A fairly high priced, but

commonly used material in applications subject to high pressure and constant

shock loads

Prednosti

-Rich Experience

More than 20 years of

experience in Rubber & Silikon molding parts development and part

production, especially to the European and North American markets, with solid understanding

of the material, technical and quality standards worldwide.

-Hiter preobrat

Na splošno nudimo aquotation v 3 delovnih dneh. Z združitvijo najnovejših proizvodnih tehnologij in naprav lahko Auwell v 5 delovnih dneh zagotovi hitre prototipe, za enostavno in majhno orodje pa lahko prvi vzorec dostavimo v 2 tednih.

-Comprehensive Solution Provider

Auwell provides

comprehensive services for Rubber & Silikon molding parts development

starting from designing, through prototyping, tooling/fixture development,

sampling, mass production, and to logistic and post-sale support.

-Toge politike nadzora kakovosti

The most rigorous quality

policy starts from material control, and is followed through to final

pre-shipment inspection for Rubber & Silikon molding parts orders. Material

certificates include the mill certificate, 3rd party chemical components, and

mechanical property reports, as well as RoHS and REACH reports upon request. We

structure our processes, creating Flow Charts and Control Plans before

production, making sure all QC processes are in accordance with ISO9001-2015

requirements and drawing specifications.

-Prilagodljiv rok plačila

For tooling, the general

payment term is 50%-50%, meant 50% deposit, 50% after first sample free. For

mass production, we offer flexible payment terms, reasonable credit terms will

be given, the client only pays when they are happy with the product they

received. For long-term projects, we offer call-off inventory services for fast

delivery requirements.

Podobni izdelki

Plastic Injection Mold for Automotive Parts

Plastic Injection Mold for Automotive Parts

Deli za brizganje plastike

Deli za brizganje plastike

Plastic Injection Overmolding

Plastic Injection Overmolding

Plastični deli za termooblikovanje

Plastični deli za termooblikovanje

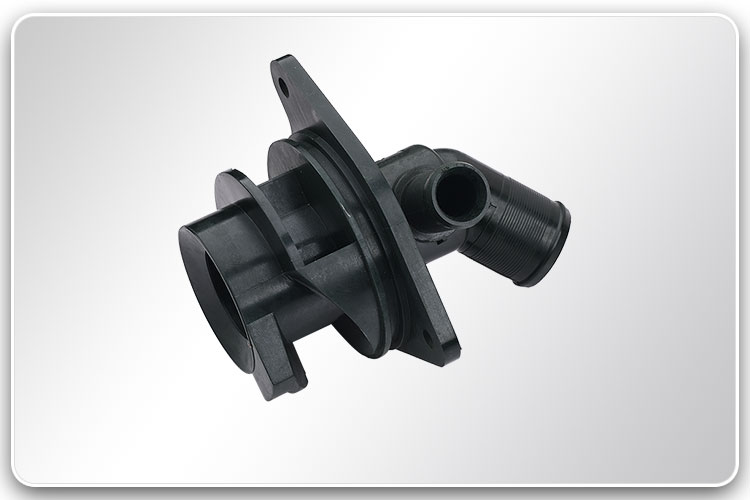

The following catalogues of Rubber & Silikon molding parts are the ones which Auwell has produced and supplied to our distinguished worldwide clients. Please click the relevant pictures for details. Please be advised, most of the products are for demonstration purpose only.

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик