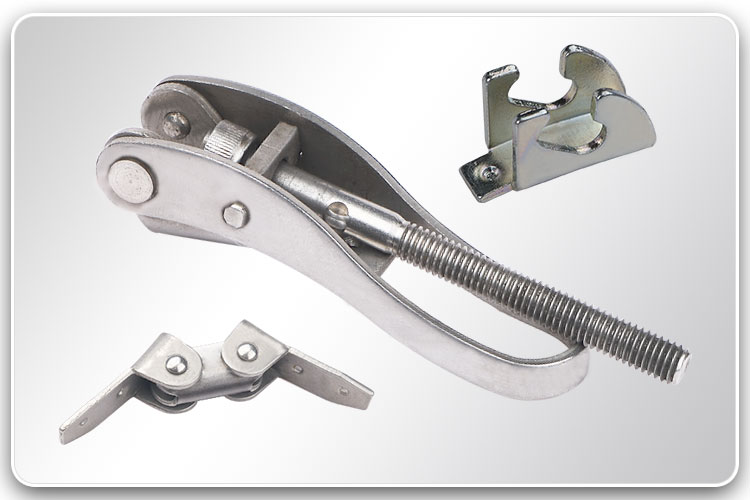

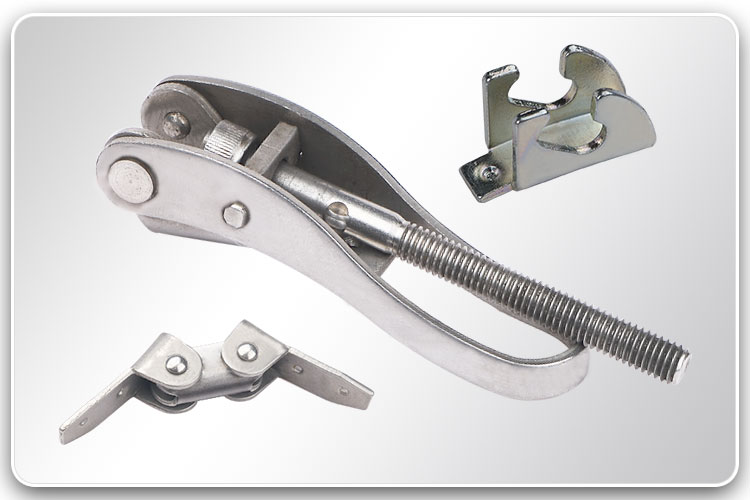

Description

Turning Parts for Spannring are the essential components for clamping ring products. If the closing side of the ring is jointed with saddle and bolt, one clamping ring set consists of generally 4 turning parts. Φ12mm and Φ14mm are the most popular diameters. A set of clamping ring consists 2 of turning parts for the clamping rings, for Φ12mm diameter, one with 6.5mm section hole and M6 thread hole for another, likewise, Φ8.5mm holes and M8 thread holes for Φ14mm turning parts for the clamping rings.

Stružilni deli iz ogljikovega jekla za vpenjalne obroče imajo pocinkane površine, privzeto je belo pocinkanje. Za lažjo identifikacijo so obračalni deli z navojnimi luknjami prevlečeni z rumenim cinkom.

The critical points for turning parts for the clamping rings control include the diameter tolerance of the arm area, the quality of the tread hole, and the burr around the thread hole tapping area. Although appearing simple, without the correct process and machines, quality issues can easily arise.

With 15 years of professional turning parts for the clamping rings production experience, Auwell has developed the most efficient way of producing such turning parts.

The following video demonstrates the manufacturing process for Turning Parts for Spannring:

Trenutno 100% naših stružnih delov za Spannring izvozimo v Nemčijo za naše ugledne stranke. Z uporabo optimizirane tehnologije in programiranja se naši izdelki izkazujejo z odlično kakovostjo, hkrati pa imajo dostopno ceno. Auwell je ponosen na svojo visoko produktivnost pri proizvodnji teh izdelkov na stroškovno učinkovit način.

The Turning Parts for Spannring products displayed are custom made exclusively for our distinguished clients. We are happy to offer competitive price to all inquiries from potential clients.

Technical Specifications

-Material: ST12, ST37, Q235B, Stainless steel 304, 316L or upon request

-Turning parts: Diameter: Φ12mm with M6 thread orΦ14mm with M6 thread or upon request

-Površinska obdelava: pocinkanje ali blanc za nerjaveče jeklo

-Package: plastic bag, carton then wooden box.

Prednosti

-Rich Experience

More than 15 years of experience in this particular turning parts for clamping rings development and production, especially to the European markets. With solid understanding of the material, technical and quality standards worldwide.

-Hiter preobrat

Generally, we provide a quotation within 2 working days. Combining the latest manufacturing technologies and facilities, Auwell can provide turning parts for clamping rings samples in just a week.

-Celovit ponudnik rešitev

Auwell provides comprehensive services for turning parts for clamping rings projects starting from designing, through prototyping, sampling, mass production, and to logistic and post-sale support.

-Toge politike nadzora kakovosti

Najbolj stroga politika kakovosti se začne od nadzora materiala in sledi do končnega pregleda pred odpremo. Certifikati o materialu vključujejo certifikat o mlinu, kemične komponente drugih proizvajalcev in poročila o mehanskih lastnostih ter poročila RoHS in REACH na zahtevo. Druga poročila vključujejo poročila o dimenzijah, debelino površinske obdelave, poročila o preskusih slane megle itd. Naše procese strukturiramo, pred izdelavo izdelamo diagrame poteka in kontrolne načrte ter se prepričamo, da so vsi procesi QC v skladu z zahtevami ISO9001-2015 in specifikacijami risb.

-Flexible Payment Term

For mass production, we offer flexible payment terms, reasonable credit terms will be given, the client only pays when they are happy with the product they received. For long-term projects, we offer call-off inventory services for fast delivery requirements.

Related Products

Sedež za vpenjalne obroče

Sedež za vpenjalne obroče

Fast Connector for Clamping Rings

Fast Connector for Clamping Rings

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик