Visokotlačni deli za tlačno litje so ena pomembnih linij izdelkov, ki jih je Auwell sodeloval z našimi proizvajalci za naše stranke po vsem svetu. Auwellmanufacture je strokovno na področju visokotlačnih delov za vlivanje cinka, orodjarstvo, razvoj, tlačno ulivanje, CNC obdelava, površinska obdelava in montaža, vsi procesi se izvajajo pod eno streho za visoko produktivnost in učinkovit nadzor kakovosti.

Technical Specifications

-Material osnovnega elementa

H13, 1.2344 (X40CRMoV51), 1.2367 (X38CrMoV5-1), H11, 1.2343 (X38CrMoV5-1)

Material za ojačitev: P20,1.2312, 1.2738

-Standard Components

HASCO, LKM standard ali izdelana po meri

-Popular Product Material

Zamak 3, Zamak 5, ZA8 itd.

-Product surface finishing

Auwell visokotlačna obdelava površin za vlivanje cinka vključuje, vendar ni omejena na: krtačo, poliranje linij, visoko brušeno poliranje, poliranje ogledal, peskanje, eloksiranje, pocinkanje, kromiranje, nikljanje, prašno lakiranje, srebrna prevleka, E - plašč, mokra barva, sito in šablon itd.

-Največja sila zapiranja obdelave

4,000 tons, part weight:

5-30,000g

Advantages

-Bogate izkušnje

More than 20 years of

experience in high pressure zinc die casting parts development and production, especially

to the European and North American markets, with solid understanding of the

material, technical and quality standards worldwide.

-Fast Turnaround

Generally, we provide a

quotation within 3 working days. Combining the latest manufacturing

technologies and facilities, Auwell can provide initial samples in just 5 weeks

for simple projects.

-Comprehensive Solution Provider

Auwell ponuja celovite storitve za visokotlačne dele za ulivanje cinka, od načrtovanja, izdelave prototipov, razvoja orodij / naprav, vzorčenja, množične proizvodnje ter logistične in poprodajne podpore.

-Rigid QC Policies

The most rigorous quality

policy starts from material control, and is followed through to final

pre-shipment inspection to high pressure zinc die casting parts orders. Material

certificates include the mill certificate, 3rd party chemical components, and

mechanical property reports, as well as RoHS and REACH reports upon request.

Other reports include dimensional reports, surface treatment thickness, and

salt fog test reports, etc. We structure our processes, creating Flow Charts

and Control Plans before production, making sure all QC processes are in accordance

with ISO9001-2015 requirements and drawing specifications.

-Flexible Payment Term

Za množično proizvodnjo bomo ponudili prilagodljive plačilne pogoje, dobili bomo razumne kreditne pogoje, kupec plača samo, ko je zadovoljen s prejetim izdelkom. Za dolgoročne projekte ponujamo storitve odpoklicnega inventarja za potrebe hitre dostave.

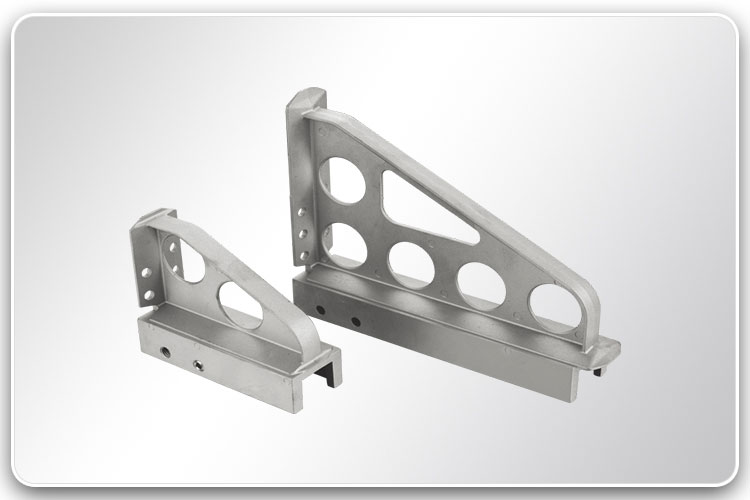

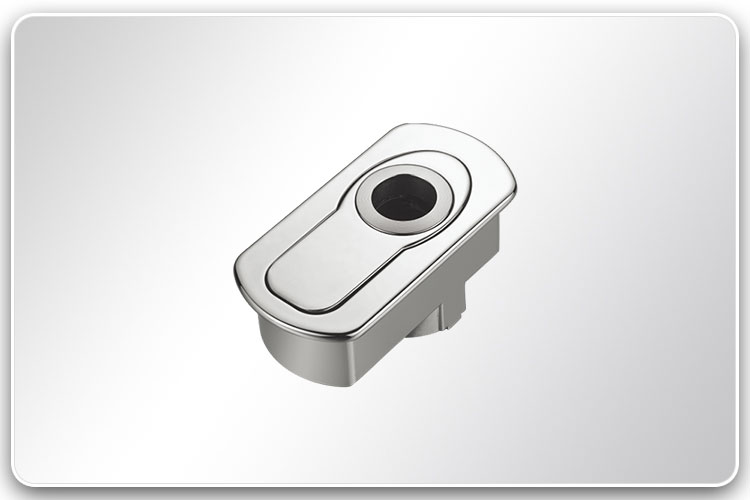

Naslednji katalogi visokotlačnih delov za tlačno litje so tisti, ki jih je Auwell izdelal in dobavil našim uglednim strankam po vsem svetu. Za podrobnosti kliknite ustrezne slike. Upoštevajte: večina izdelkov je namenjena samo predstavitvi.

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик