Opis

Vpenjalni obročki iz Auwellove linije izdelkov so mehanizem, ki linearno spaja cevi / kanale2 z vpenjanjem predhodno razvitih robov cevi.

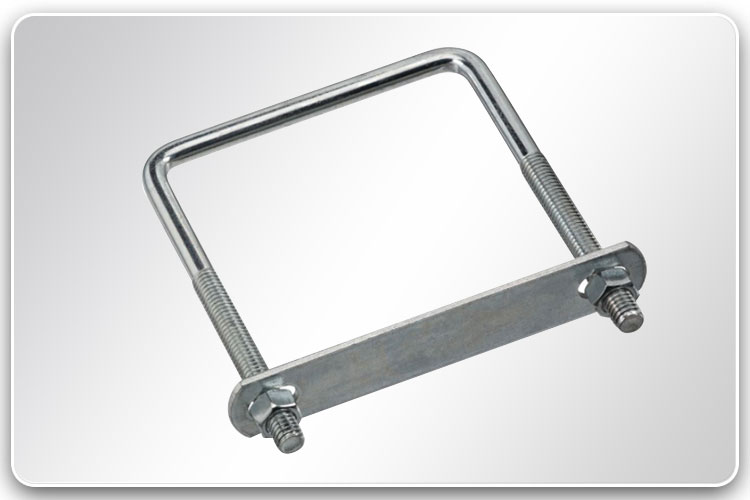

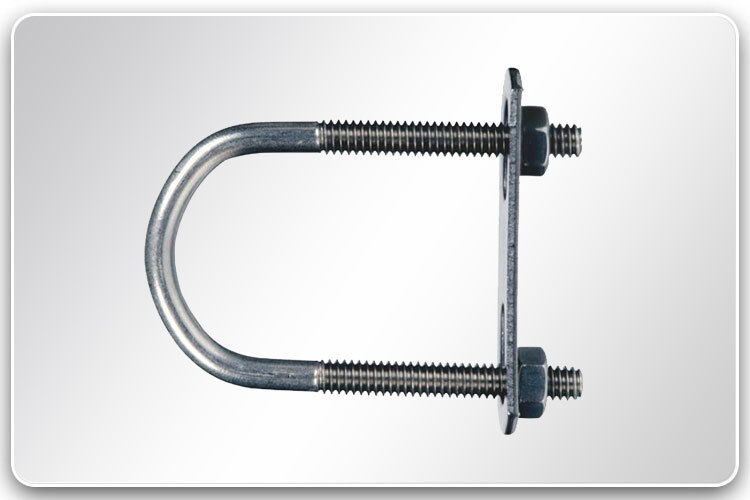

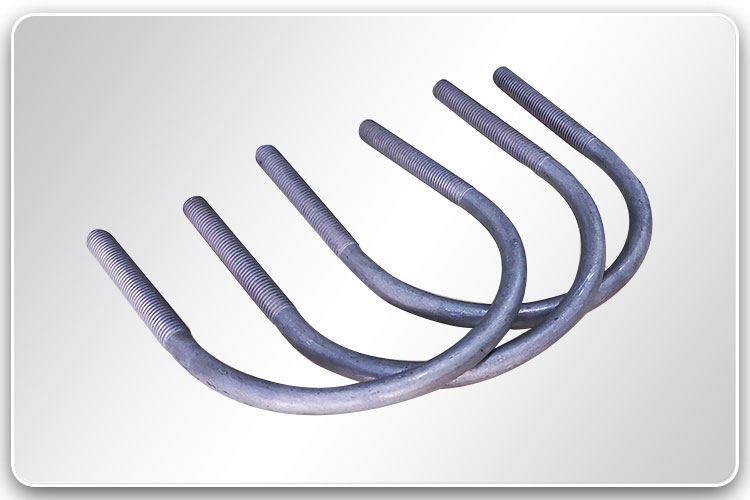

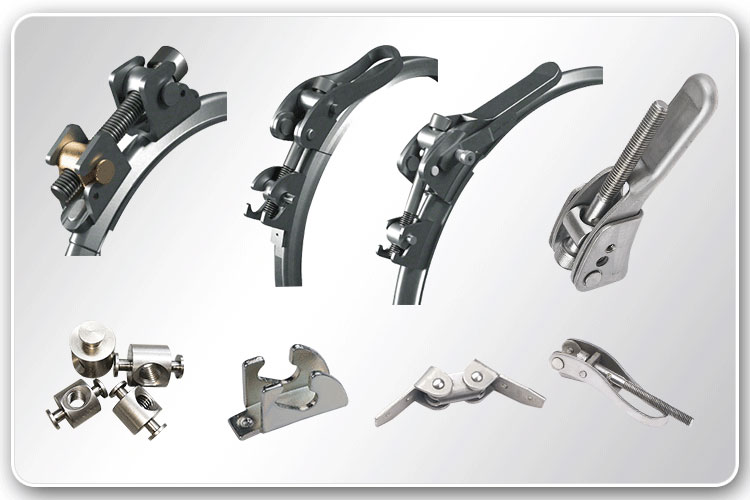

The clamping ring is formed by a flat steel bar to the desired shape and

diameter. It consists 2 half rings, the

closing side is connected by a screw bolt or hinge, the opening side also has 2

ways of assembly - the screw mechanism or quick release (fast connector)

mechanism. For both assembling methods, the ring can be tightened and adjusted

to the desired tightness.

In general, the diameter of clamping rings range from 80mm to 630mm, the profile of the rings can be U shaped, V shaped, or custom made upon clients’ request. The thickness of the rings range from 1mm to 3mm. If the pipeline is for liquid transportation, rim seals will be used, the seal material can be NBR or silicone, with a maximum pressure of up to 4.5bar.

Pred vpenjanjem

Pred vpenjanjem

Po vpenjanju

Po vpenjanju

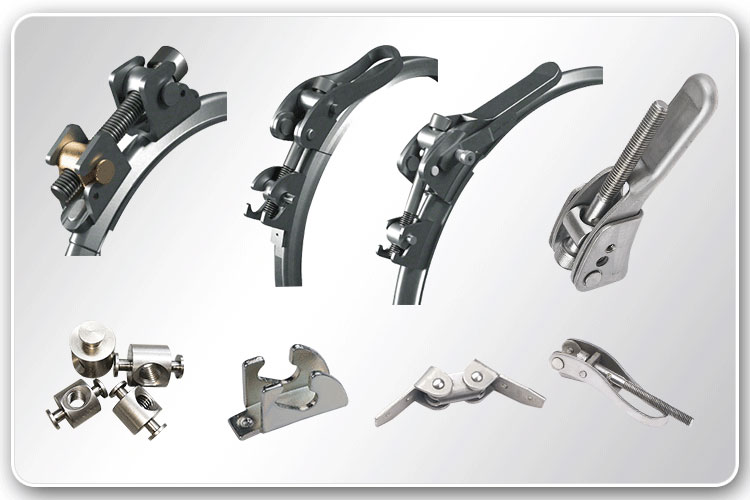

The half clamping ring parts are assembled with a saddle (stamping parts), hinges, and fast connectors by butt welding followed by hand welding for reinforcement. Before assembling the 2 halves, for carbon steel or stainless steel parts, zinc plating and shot blasting may be applied respectively upon request.

Auwell has more than 15 years of experience in manufacturing and supplying components for clamping ring products including fast connectors, hinges, saddles (stamping parts), and turning parts, at this moment, 100% of products exported to Germany for our distinguished clients. By using optimized technology and programming, our products have been proven as excellent in quality at an affordable price. Auwell is proud of its high productivity for producing these products in a cost-effective way.

The Spannring Parts displayed are custom made exclusively for our distinguished clients. We are happy to offer competitive price to all inquiries from potential clients.

Tehnične specifikacije

-Material: ST12, ST37, Q235B, nerjaveče jeklo 304, 316L ali na zahtevo

-Saddle thickness: 2.5mm

-Turning parts: Diameter: Φ12mm with M6 thread orΦ14mm with M6 thread or upon request

-Turning parts made by custom made CNC lathe, full automatic production, sedlo izdeluje progresivna matrica za kakovost

doslednost in večja produktivnost.

Prednosti

-Rich Experience

Več kot 15 let izkušenj pri razvoju in proizvodnji komponent vpenjalnih obročev, zlasti na evropskih trgih. S trdnim razumevanjem materialnih, tehničnih in kakovostnih standardov po vsem svetu.

-Hiter preobrat

Generally, we provide a quotation within 3 working days. Combining the latest manufacturing technologies and facilities, Auwell can provide fast prototypes in just 3 weeks for simple projects including fast connectors.

-Comprehensive Solution Provider

Auwell provides comprehensive services for clamping ring components projects starting from designing, through prototyping, tooling/fixture development, sampling, mass production, and to logistic and post-sale support.

-Toge politike nadzora kakovosti

Najbolj stroga politika kakovosti se začne od nadzora materiala in sledi do končnega pregleda pred odpremo. Certifikati o materialu vključujejo certifikat o mlinu, kemične komponente drugih proizvajalcev in poročila o mehanskih lastnostih ter poročila RoHS in REACH na zahtevo. Druga poročila vključujejo poročila o dimenzijah, debelino površinske obdelave, poročila o preskusih slane megle itd. Naše procese strukturiramo, pred izdelavo izdelamo diagrame poteka in kontrolne načrte ter se prepričamo, da so vsi procesi QC v skladu z zahtevami ISO9001-2015 in specifikacijami risb.

-Flexible Payment Term

Plačila za orodja morajo biti vnaprej plačana. Za množično proizvodnjo ponujamo prilagodljive plačilne pogoje, podani bodo razumni kreditni pogoji, stranka plača le, če je zadovoljna s prejetim izdelkom. Za dolgoročne projekte ponujamo storitve odpoklicnega inventarja za potrebe hitre dostave.

Aplikacije

Clamping rings have widely been used in almost all industrial sectors including:

-Avtomobilizem

-Agriculture Machinery

-Stroji za živila

-Farmacevtska industrija

-Oil industry

-Gradnja

-Prevoz

The following catalogues of clamping rings components are the ones which Auwell has produced and supplied to our distinguished clients. Please click the relevant pictures for details. Please be advised, most of the products are for demonstration purpose only.

Hitri priključek za vpenjalne obroče

Hitri priključek za vpenjalne obroče

Saddle for Clamping Rings

Saddle for Clamping Rings

Stružni deli za vpenjalne obroče

Stružni deli za vpenjalne obroče

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик