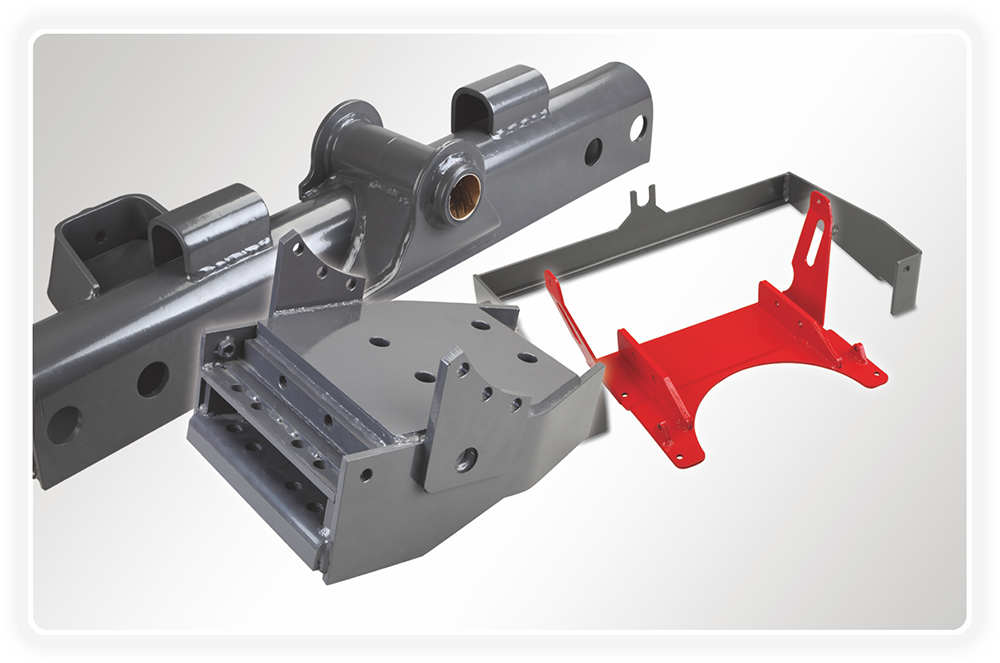

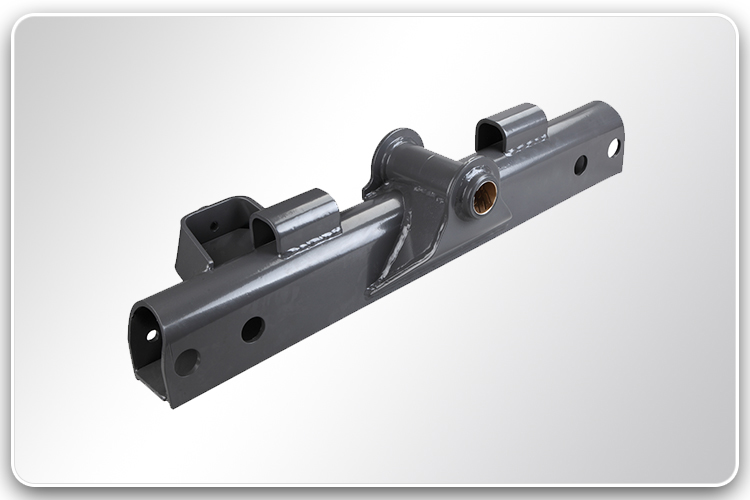

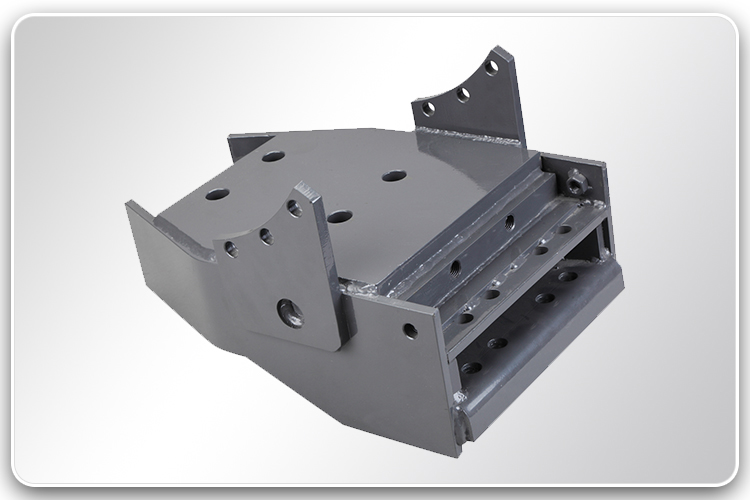

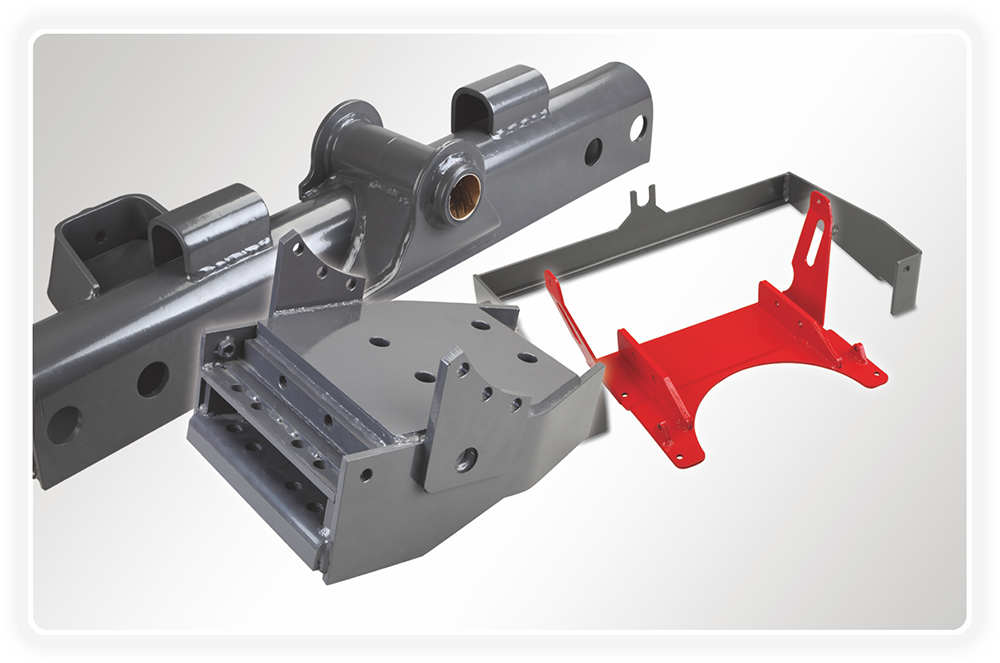

Auwell je leta 2011 začel z razvojem OEM delov za pločevinaste kmetijske stroje, večinoma za serijo AGCO MASSEY-FERGUSON BX200. Zajema različne sektorje, od preprostih delov za vtiskovanje do težkih in kompleksnih skupin za sestavljanje.

Industrija kmetijskih strojev ima svoje edinstvene zahteve, ključnega pomena je uporaba pravega materiala in proizvodnega postopka v skladu z zahtevami za risanje. Auwell organizira proizvodnjo OEM delov za kmetijske stroje proizvajalca TS16949, registriranega in izkušenega, da bi zagotovil kakovost izdelka.

Postopek izdelave OEM delov kmetijskih strojev vključuje 4 korake - rezanje, oblikovanje, sestavljanje in površinska obdelava.

-Postopek rezanja

We offer various cutting options with thickness ranged from 1 mm to 150mm, this includes oxygen cutting, laser cutting, plasma cutting. For small parts, the stamping is the most common way for material blanking.

-Postopek oblikovanja

Postopek oblikovanja običajno vključuje upogibanje, hidravlično oblikovanje stiskalnice z matrico, prebijanje in rezkanje. Narava zasnove delov določa uporabljeno metodo. Razbarvanje je bistven postopek pred varjenjem in sestavljanjem.

-Assembling

Pri OEM delih za kmetijske stroje je glavni postopek sestavljanja varjenje. Armature je treba predhodno načrtovati in izdelati tako, da izdelek po varjenju ne bo popačen. Nekatera območja po sestavljanju zahtevajo rezkanje. Za pregled kakovosti je vnaprej razvit niz merilnikov, ki zagotavljajo popolno funkcionalnost izdelka.

-Površinska obdelava

The normal surface treatment processes of Agriculture Machinery OEM Parts include electrophoresis (KTL), powder coating, painting, and zinc plating. For all surface treatment, we offer coating adhesion, thickness, and salt fog tests or, other tests to be conducted upon request. Anodizing is available for aluminum materials.

Tehnične specifikacije

-Material

Blago jeklo, nerjaveče jeklo, baker, medenina, aluminij in legirano jeklo.

-Kapaciteta stroja

1,200 ton hydraulic press machine, 800 ton stamping machine, material cutting thickness up to 150mm for oxygen cutting, 60mm for plasma cutting, and 25mm for laser cutting. Maximum part size: 2,000*1,500mm.

-Druge specifikacije

Auwell is capable in designing and developing necessary tools for Agriculture Machinery OEM Parts including forming dies, fixtures for welding, and test gauges for mass production QC. CMM is available for sample dimensional inspection. Surface treatment includes KTL, powder coating, painting and zinc plating. Flow Chat and Control Plan will be submitted to the client for discussion before production. PPAP documents are submitted together with the initial samples.

Advantages

-Bogate izkušnje

More than 9 years of experience in Agriculture Machinery OEM Parts development and production, especially to the European and North American markets, with solid understanding of the material, technical and quality standards worldwide.

-Hiter preobrat

Generally, we provide a quotation within 3 working days. Combining the latest manufacturing technologies and facilities, Auwell can provide fast prototypes in just 3 weeks for simple projects.

-Comprehensive Solution Provider

Auwell provides comprehensive services for Agriculture Machinery OEM Parts starting from designing, through prototyping, tooling/fixture development, sampling, mass production, and to logistic and post-sale support.

-Toge politike nadzora kakovosti

The most rigorous quality policy starts from material control, and is followed through to final pre-shipment inspection to griculture Machinery OEM Parts orders. Material certificates include the mill certificate, 3rd party chemical components, and mechanical property reports, as well as RoHS and REACH reports upon request. Other reports include dimensional inspection, surface treatment thickness, and salt fog test reports, etc. We structure our processes, creating Flow Charts and Control Plans before production, making sure all QC processes are in accordance with TS16949 requirements and drawing specifications.

-Prilagodljiv rok plačila

Plačila za orodja morajo biti vnaprej plačana. Za množično proizvodnjo ponujamo prilagodljive plačilne pogoje, podani bodo razumni kreditni pogoji, stranka plača le, če je zadovoljna s prejetim izdelkom. Za dolgoročne projekte ponujamo storitve odpoklicnega inventarja za potrebe hitre dostave.

The following catalogues of Agriculture Machinery OEM Parts are the ones which Auwell has produced and supplied to our distinguished worldwide clients. Please click the relevant pictures for details. Please be advised, most of the products are for demonstration purpose only.

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик