Opis

Injekcija molding is a proizvodnja process for producing parts by injecting molten material into a mold. Plastic Injekcija Molding is one of the most frequently used proizvodnja

processes for creating plastic parts. Thanks to its high-precision,

repeatability, and cost efficiency at scale, plastic injection molding is used for

a variety of products and parts from the smallest insert up to large automotive

& aerospace parts.

Postopek brizganja plastike zahteva stroj za brizganje, surov plastični material in obdelani kalup. Surovi plastični material se najprej stopi v brizgalni enoti in nato vbrizga v kalup, kjer se ohladi in strdi v končni plastični del.

The key steps in the injection molding process include:

-Clamping

The two sides

of the mold are closed and clamped shut.

-Injekcija

The material is fed into

the machine and pushed towards the mold. While this is happening, the material

is melted by heat and pressure. The plastic is then injected into the mold,

this process is called “Shot”.

-Hlajenje

The plastic in

the mold cools and solidifies into the shape of the part.

-Ejection

After the part

cools, it is ejected from the mold.

Auwell ponuja dva poslovna modela, ki ustrezata potrebam naročnika za projekte brizganja plastike. In sicer orodja za dobavo samo modeli ali modeli končnih izdelkov.

-Tooling Only Models

For this business model,

Auwell offers the tooling design based on the product design and machine data

for client confirmation, the details include tooling structure, lifetime,

tooling material, hardness, etc. Clients may provide completed tooling designs

for production. For this tooling only option, for standard parts, we will use the

most common with globally recognized one for easy maintenance. In general, this

option is preferred for large size and high-volume products, Plastic

Injekcija Tooling Automotive is a typical catalogue for this business

model.

-Modeli končnih izdelkov

For this business model, Auwell is responsible for the plastic injection molding parts, and to meet the client’s specifications. The type of injection machine and tooling structure/design used is decided by our team. For this business model, once the client pays the tooling cost, Auwell will be responsible for tooling maintenance and replacement for the entire product lifetime. This model is preferred for small sizes and precise plastic injection molding parts. Please refer to “Plastic Injekcija Partsâ € oddelek za več podrobnosti.

Another key difference of the two-business model is, for “Tooling Only

Model”, the mold cost is considerable higher than “Final Products Model” as for

“Final Products Model”, Auwell does not make any margin from the tooling

development. For “Final Products Model”, if the clients want to take the mold

or, shift to another supplier, it is not guaranteed that the mold works

properly at another machine at another manufacture, and, a certain proportion

of mold development cost will be charged before mold transferring.

Poleg brizganja plastike nudimo tudi naslednje storitve:

-Rapid 3D printed prototypes

-Preoblikovanje

-Insert molding

-Thermoforming

-Oblikovanje gume in silikona

Technical Specifications

-Material

Naslednji plastični material, ki je na voljo za naše storitve brizganja plastike:

Ø PA 6/6 | Polyamide 6/6, Nylon 6/6

Ø PARA | Polyaryl Amide

Ø PBT | Polybutylene Terephthalate, Valox

Ø PBT-PET | Polibutilen tereftalat-polietilen tereftalat

Ø PC | Polycarbonate

Ø PC-ABS | Polikarbonat-akrilonitril butadien stiren

Ø PC-PBT | Polycarbonate-Polybutylene Terephthalate, Xenoy

Ø PC-PET | Polycarbonate-Polyethylene Terephthalate

Ø PCT | Polycyclohexylenedimethylene Terephthalate

Ø PE | Polyethylene

Ø PE-PP | Polietilen-polipropilen

Ø PE-PS | Polietilen-polistiren

Ø PEBA | Polieter blok amid

Ø PEEK | Polyether Ether Ketone

Ø PEI | Polieterimid, Ultem

Ø PES | Polyether Sulfone

Ø PET | Polietilen tereftalat, Rynite

Ø PLA | Polilaktična kislina

Ø PMMA | Polymethyl Methacrylate, Acrylic

Ø POM | Acetalni polioksimetilen, Delrin

Ø PP | Polipropilen

Ø PPA | Poliftalamid

Ø PPS | Polyphenylene Sulfide, Ryton

Ø PS | Polistiren

Ø PS-OZO | Polistiren-polifenil etri, noril

Ø PSU | Polysulfone, Udel

Ø PVC | Polyvinyl Chloride (Shore D)

Ø PVDF | Polyvinylidene Fluoride

Ø SAN | Styrene Acrylonitrile

Ø TPO | Termoplastični poliolefin

Ø TPU | Termoplastični poliuretan (Shore D)

Ø Smola po naročilu

-Moldbase

LKM, HASCO, 1.1730, S50C, S55C, 1050, 1055

-Aktivni elementi

Ø P20, 1.2311, 1.2312, 1.2738, 1.2343, 1.2344, H11, H13, 420

Ø ASSAB: 718, 718S, 718H, S316/S316H/S316 SUP/S316H SUP, POLMAX/168

Ø SAARSTAHL: GS738, GS2311, GS2312, GS638, GS688, GS2316

Ø DAIDO: NAK80, NAK55, PX88, PX4, PX5, S-Star(A)

Ø BOHLER: M201, M202, M238, M300 ESR, M310 ESR, M310H ESR

-Hotrunner

YUDO, INCOE

-Površina plesni

Foto jedkanje, erodestruktura, brizganje, poliranje linij, visoko brušeno poliranje, zrcaljenje.

-Machines: 100-3,000 ton

closing force

Prednosti

-Bogate izkušnje

More than 20 years of

experience in plastic injection molding tooling development and part production,

especially to the European and North American markets, with solid understanding

of the material, technical and quality standards worldwide.

-Hiter preobrat

Generally, we provide a

quotation within 3 working days. Combining the latest proizvodnja

technologies and facilities, Auwell is able to provide fast prototypes in 3

working days, for simple and small size tooling, we are able to deliver first

sample in 4 weeks.

-Comprehensive Solution Provider

Auwell provides

comprehensive services for plastic injection molding projects starting from

designing, through prototyping, tooling/fixture development, sampling, mass

production, and to logistic and post-sale support.

-Toge politike nadzora kakovosti

Najbolj stroga politika kakovosti se začne od nadzora materiala in sledi do končnega pregleda pred odpremo. Potrdila o materialu vključujejo potrdilo o mlinu, kemične komponente drugih proizvajalcev in poročila o mehanskih lastnostih ter poročila RoHS in REACH na zahtevo. Procese strukturiramo tako, da pred proizvodnjo ustvarimo diagrame poteka in nadzorne načrte, pri čemer se prepričamo, da so vsi procesi QC v skladu z zahtevami ISO9001-2015 in specifikacijami risb.

-Prilagodljiv rok plačila

Za orodje je splošni rok plačila 50% -40% -10%, kar pomeni 50% pologa, 40% po prvem brezplačnem vzorcu in 10% 2 tedna po tem, ko stranka prejme orodje ali prvo serijsko dostavo izdelka. Za proizvodnjo formass ponujamo prilagodljive plačilne pogoje, podani bodo razumni kreditni pogoji, stranka plača le, če je zadovoljna z izdelkom, ki ga je prejela. Za dolgoročne projekte ponujamo storitve odpoklicnega inventarja za zahteve glede hitre dostave.

Aplikacije

-Izdelki za brizganje plastike se pogosto uporabljajo v skoraj vseh industrijskih sektorjih, vključno z:

-Letalski in vesoljski sektor

-Automotive

-Agriculture Machinery

-Energy

-Elektronika

-Construction

-Prevoz

-Industrijski

-Consumer Products

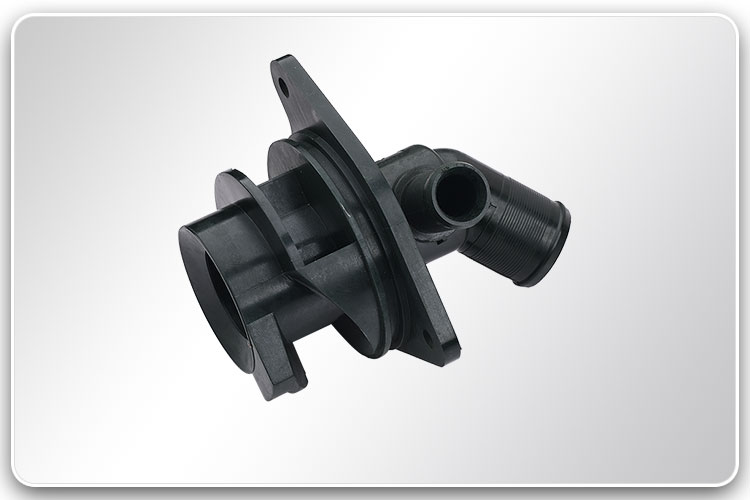

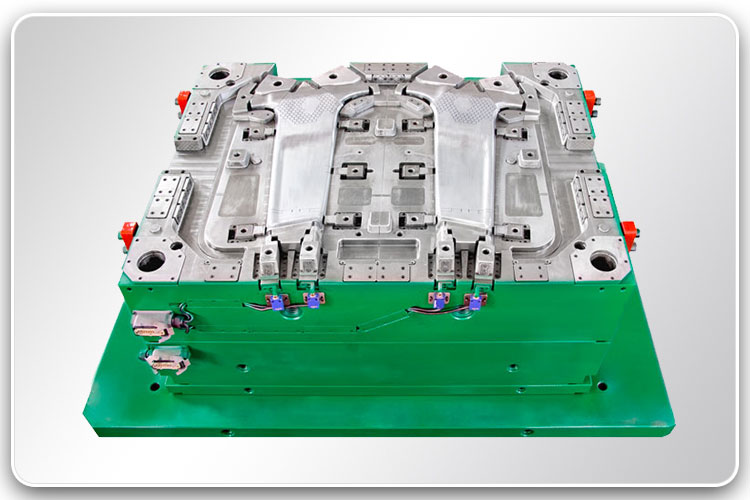

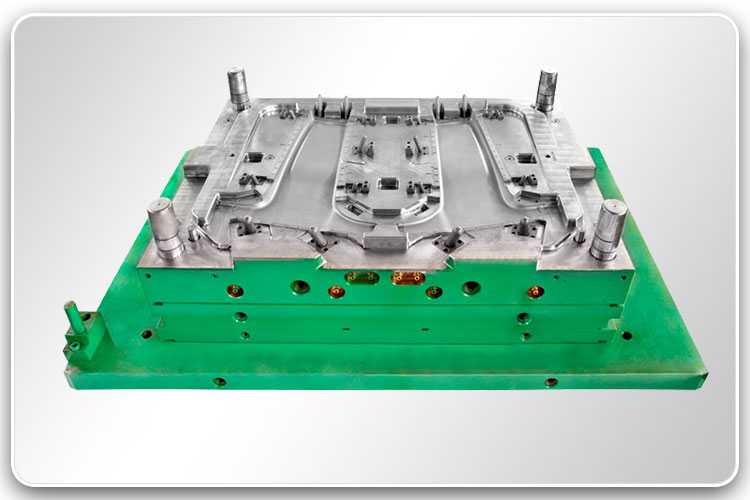

The following catalogues of plastic injection molding products

are the ones which Auwell has produced and supplied to our distinguished

worldwide clients. Please click the relevant pictures for details. Please be

advised, most of the products are for demonstration purpose only.

Plastic Injekcija Mold for Automotive Parts

Plastic Injekcija Mold for Automotive Parts

Plastic Injekcija Parts

Plastic Injekcija Parts

Plastic Injekcija Preoblikovanje

Plastic Injekcija Preoblikovanje

Plastični deli za termooblikovanje

Plastični deli za termooblikovanje

Kalupi iz gume in silikona

Kalupi iz gume in silikona

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик