Globoko vlečenje in predenje je pravzaprav dodaten postopek izdelave žigosanja. Kadar so izdelki s skodelico, škatlo in drugimi zapleteno ukrivljenimi votlimi oblikami, ki jih ni mogoče oblikovati s postopkom žigosanja, ali če je globina vlečenih delov večja od premera, je lahko globoko vlečenje in predenje pravi postopek izdelave .

Globok postopek vlečenja in predenja

zahteva, da je material nizkoogljično jeklo z visokim raztezkom za odlično

oblikovanje uspešnosti. Očitno bi bila najboljša možnost nizkoogljično jeklo

aluminij in baker sta dober material za ta postopek. Lahko iz nerjavečega jekla

možnost tudi za globok postopek vlečenja in predenja, vendar lahko zahteva toploto

obdelava za mehčanje materiala pred naslednjim postopkom.

The surface

treatment for deep drawing & spinning parts can be:

-Poliranje

-Zinc-plating

-Nickel plating

-Chrome plating

-Posrebritev

-KTL

-Hot dip galvanization

-Slika

-Prašni premaz

-Anodizing

Auwell ima več kot 20 let razvoja in proizvodnje globokih vlečnih in predilnih delov. Auwellove bogate izkušnje, stroškovno učinkovit, hiter obtok in velike proizvodne zmogljivosti ter ugodni plačilni pogoji so pri naših strankah dosegli velik ugled.

Konkurenčne prednosti

-Rich Experience

Več kot 20 let izkušenj v razvoju in proizvodnji poglobljenega vlečenja in predenja delov, zlasti na evropskih in severnoameriških trgih, s solidnim razumevanjem materialov, tehničnih in kakovostnih standardov po vsem svetu.

-Hiter preobrat

Generally, we provide a quotation within 3 working days. Combining the

latest manufacturing technologies and facilities, Auwell can provide fast

prototypes for deep drawing & spinning parts in just 2 weeks for simple projects.

-Comprehensive Solution Provider

Auwell provides comprehensive services for deep drawing & spinning parts

development starting from designing, through prototyping, tooling/fixture

development, sampling, mass production, and to logistic and post-sale support.

-Toge politike nadzora kakovosti

The most rigorous quality policy starts from material control, and is

followed through to final pre-shipment inspection. Material certificates

include the mill certificate, 3rd party chemical components, and mechanical

property reports, as well as RoHS and REACH reports upon request. Other reports

include dimensional reports, surface treatment thickness, and salt fog test

reports, etc. We structure our processes, creating Flow Charts and Control Plans

before production, making sure all QC processes are in accordance with

ISO9001-2015 requirements and drawing specifications.

-Flexible Payment Term

Tooling payments need to be pre-paid. For mass production, we offer

flexible payment terms, reasonable credit terms will be given, the client only

pays when they are happy with the product they received. For long-term

projects, we offer call-off inventory services for fast delivery requirements.

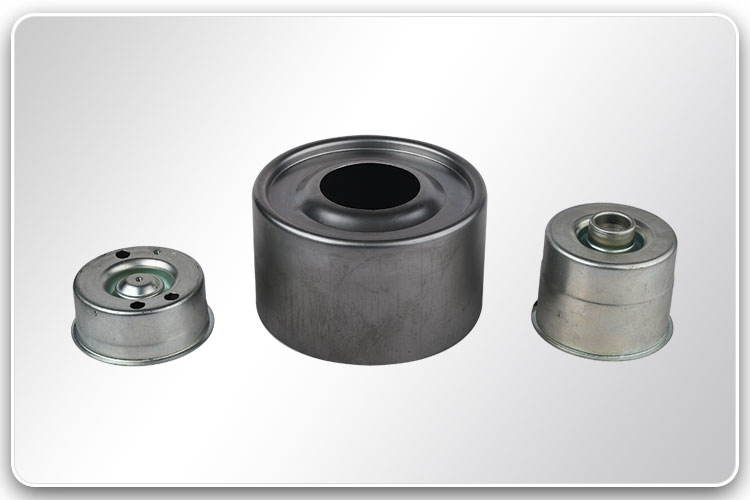

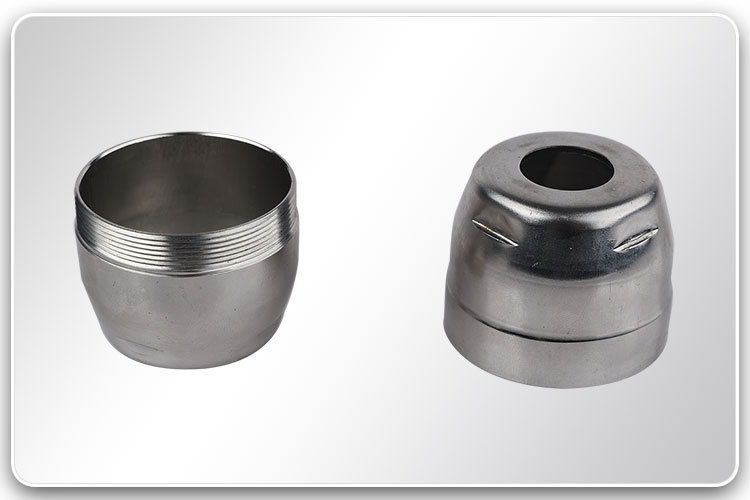

Prikazani deli globokega vlečenja in predenja v tem razdelku so nekateri izdelki, ki jih je Auwell razvil za naše stranke, vsi deli za vtiskovanje so izdelani v OEM, naslednji izdelki so samo za predstavitev. Če morajo naročniki razviti globoke dele za vlečenje in predenje, je dobrodošlo, da nas kontaktirate za podrobnosti.

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик