Description

Casting is a manufacturing process in which a liquid material is usually poured into a mold, which contains a hollow

cavity of the desired shape, and then allowed to solidify. The solidified part

is also known as a casting, which is ejected or broken out of the mold to

complete the process.

Najpogostejši kovini, obdelani za ulivanje, so aluminij in litoželezo. Za izdelavo ulitkov v livarnah pa se uporabljajo tudi druge kovine, kot so nerjaveče jeklo, legirano jeklo, bron, medenina, magnezij in cink.

Casting is most commonly used for making complex shapes that would be

difficult or uneconomical to make via other methods. The casting process

typically includes 4 steps - cutting, forming, assembling, and surface

treatment.

-Izdelava plesni

In the casting process,

a pattern is made in the shape of the desired part. Simple designs can be made

in a single piece or solid pattern. More complex designs are made in two parts,

called split patterns. The pattern is made of wax, wood, plastic, or

metal. The molds are constructed through several different processes depending on

the type of foundry, metal to be casted, the number of parts to be produced,

size of the casting, and complexity of the casting.

- Melting

Melting is performed in

a furnace. The process includes melting the charge, refining the melt, adjusting

the melt chemistry, and tapping into a transport vessel. Refining is done to remove harmful gases and elements from the molten metal

to avoid casting defects.

-Pouring

V livarni se staljena kovina vlije v kalupe. Nalivanje lahko izvedemo z gravitacijo ali pa mu pomagamo z vakuumskim plinom ali plinom pod pritiskom.

- Shakeout

The solidified metal

component is then removed from its mold. Where the mold is sand-based, this can

be done by shaking or tumbling.

- Degating

Degatacija je odstranitev glav, tekačev, vrat in riserjev z ulitka. Tekače, vrata in dvižne roke lahko odstranite z rezalnimi gorilniki, tračnimi žagami ali keramičnimi rezalnimi listi.

-Toplotna obdelava

Toplotna obdelava je skupina industrijskih in kovinskih procesov, ki se uporabljajo za spreminjanje fizikalnih in včasih kemičnih lastnosti materiala.

-Čiščenje površin

After degating and heat

treatment, sand or other molding media may remain adhered to the casting. To

remove any mold remnants, the surface is cleaned using a blasting process.

Numerous materials may be used to clean cast surfaces, including steel, iron,

other metal alloys, aluminum oxides, glass beads, walnut shells, baking powder,

and many others.

-Dokončanje

The final step in the

process of casting usually involves grinding, sanding, or machining the component to achieve the desired dimensional accuracies,

physical shape, and surface finish.

Tehnične specifikacije

-Material za ulivanje

Železo, blago jeklo, legirano jeklo, nerjaveče jeklo, aluminij, bron, medenina in cink.

-Na voljo so naslednji postopki za izdelavo ulitkov po naravi zasnove.

ØUlivanje peska - pesek iz zelene ali smole.

ØLost-foam casting — Polystyrene pattern with a mixture of ceramic and sand mold.

ØInvestment casting — Wax or similar sacrificial pattern with a ceramic mold.

ØCeramic mold casting — Plaster mold.

ØVlivanje z V-postopkom - sesanje s termoformirano plastiko za oblikovanje peščenih kalupov. Brez vlage, gline ali smole.

ØUlivanje pod tlakom - kovinski kalup.

ØUlivanje gredic (ingotov) - preprost kalup za izdelavo kovinskih ingotov, običajno za uporabo v drugih livarnah.

Poleg tega, da našim strankam zagotavljamo ulitke, mostof izdelkov Auwell ponuja tudi nadaljnjo obdelavo in obdelavo površin.

Forging is a manufacturing process involving the shaping of metal using

localized compressive forces. Generally, Auwell does not offer forging, but only

using forged parts as pre-material for further processing.

Advantages

-Bogate izkušnje

More than 20 years of

experience in casting products development and production, especially to the

European and North American markets, with solid understanding of the material,

technical and quality standards worldwide.

-Hiter preobrat

Generally, we provide a

quotation within 3 working days. Combining the latest manufacturing

technologies and facilities, Auwell can provide fast prototypes in just 2 weeks

for simple projects.

-Celovit ponudnik rešitev

Auwell ponuja celovite storitve za ulitke, od zasnove, oblikovanja prototipov, razvoja orodij / naprav, vzorčenja, množične proizvodnje do logistike in poprodajne podpore.

-Rigid QC Policies

The most rigorous quality

policy starts from material control, and is followed through to final

pre-shipment inspection. For quality control of casting parts, we provide set

of test reports including chemical components, mechanical property, X-ray test,

metallographic analysis report etc. For dimension inspection, we offer 3D

scanning report, also CMM is available for inspection. We structure our

processes, creating Flow Charts and Control Plans before production, making

sure all QC processes are in accordance with ISO9001-2015 requirements and

drawing specifications.

-Flexible Payment Term

Plačila za orodja morajo biti vnaprej plačana. Za množično proizvodnjo ponujamo prilagodljive plačilne pogoje, podani bodo razumni kreditni pogoji, stranka plača le, če je zadovoljna s prejetim izdelkom. Za dolgoročne projekte ponujamo storitve odpoklicnega inventarja za potrebe hitre dostave.

Applications

Casting fabrication products have widely been used in almost all

industrial sectors including:

- Aerospace and defense

- Automotive

-Kmetijski stroji

- Energy

-Elektronika

- Construction

-Prevoz

- Industrial

- Consumer Products

The following catalogues of casting products are the

ones which Auwell has produced and supplied to our distinguished worldwide

clients. Please click the relevant pictures for details. Please be advised,

most of the products are for demonstration purpose only.

Ulivanje iz nerjavečega jekla

Ulivanje iz nerjavečega jekla

Stainless Steel Casting for GEBO

Stainless Steel Casting for GEBO

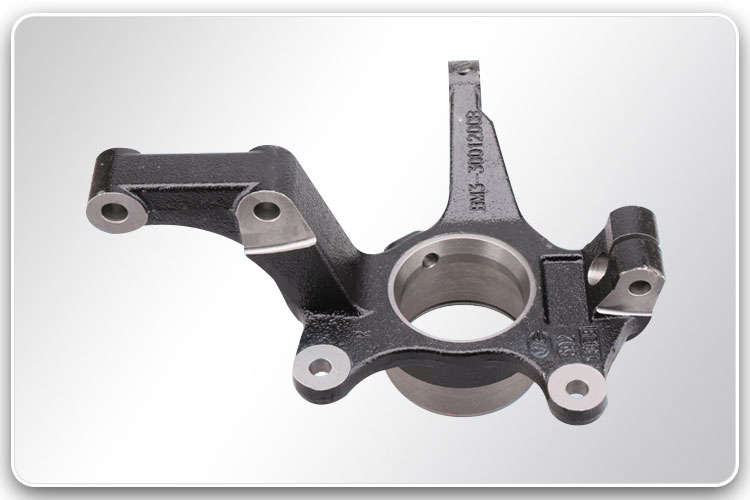

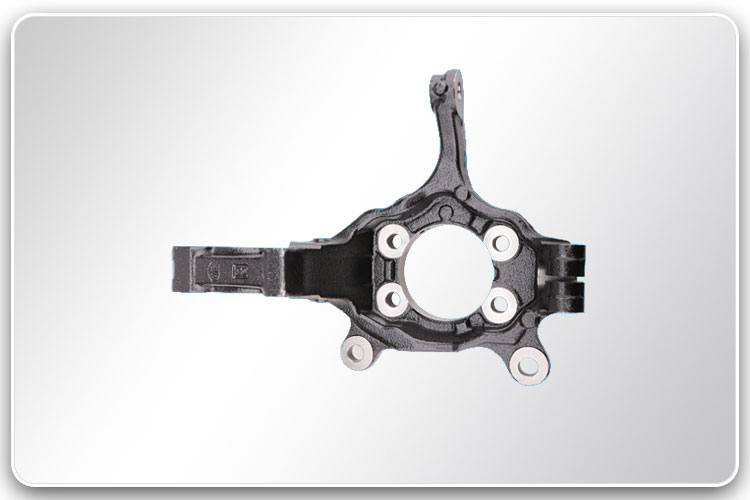

Krmilni zglob

Krmilni zglob

Forging Spline Connector

Forging Spline Connector

Forging Wheel Hub

Forging Wheel Hub

AGV aluminijasta podlaga

AGV aluminijasta podlaga

Alu. Gravitacija in litje peska

Alu. Gravitacija in litje peska

Ulivanje gravitacije med peskom in medenino

Ulivanje gravitacije med peskom in medenino

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик