Duplex stainless steels

are a family of stainless steels. They are designed to provide better corrosion

resistance, particularly chloride stress corrosion and chloride pitting

corrosion, and higher strength than standard austenitic stainless steels such

as Type 304 or 316. The main differences in composition, when compared with an

austenitic stainless steel is that the duplex steels have a higher chromium

content, 20–28%; higher molybdenum, up to 5%; lower nickel, up to 9% and

0.05–0.50% nitrogen. Both the low nickel content and the high strength

(enabling thinner sections to be used) give significant cost benefits. They are

therefore used extensively in the offshore oil and gas industry for pipework

systems, manifolds, risers, etc and in the petrochemical industry in the form

of pipelines and pressure vessels. In addition to the improved corrosion

resistance compared with the 300 series stainless steels duplex steels also

have higher strength.

EN 1.4462 duplex nerjaveče jeklo je eno od zastav za izdelke iz nerjavečega jekla, ki smo ga razvili za naše stranke, imenovano je tudi 2205, X2CrNiMoN22-5-3 je njegova oznaka jekla. To je tipični standardni dupleks (obseg PREN: 28 - 38), ki je bila široko uporabljena.

|

Oznaka

|

Standardno

|

Kemične sestave (%)

|

|

C

|

Si

|

Mn

|

P

|

S

|

Cr

|

Mo

|

Ni

|

N

|

Cu

|

|

1.4462

|

EN 10088-1 2014

|

Maks.

|

0.03

|

1.00

|

2.00

|

0.035

|

0.015

|

23.00

|

3.50

|

6.50

|

0.20

|

-

|

|

Min.

|

|

|

|

|

|

21.00

|

2.50

|

4.50

|

0.05

|

|

|

Oznaka

|

Standard

|

Physical Property

|

|

0,2 Proof (MPA)

|

Tensile (MPA)

|

Raztezek (%)

|

|

1.4462

|

EN 10088-1 2014

|

Maks.

|

|

880

|

|

|

Min.

|

450

|

650

|

25

|

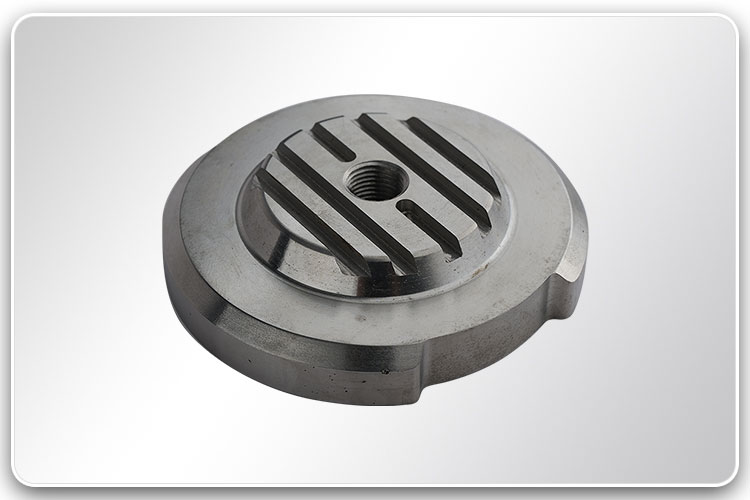

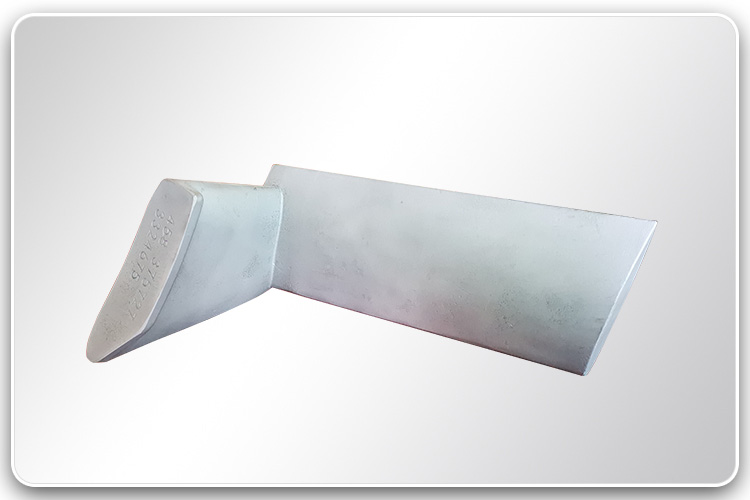

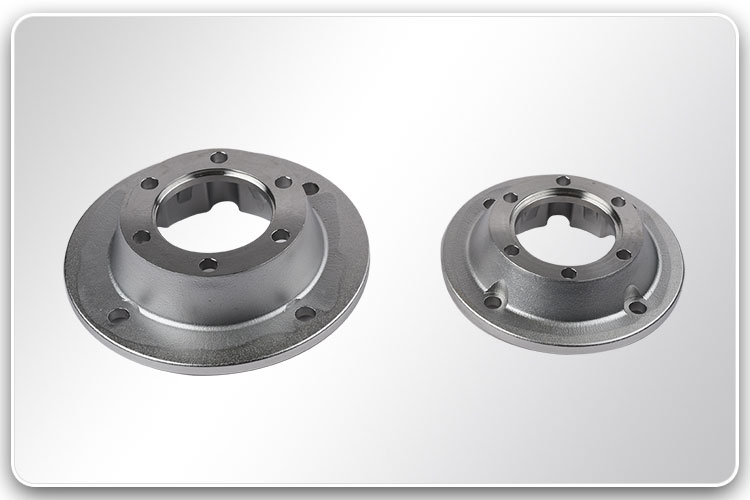

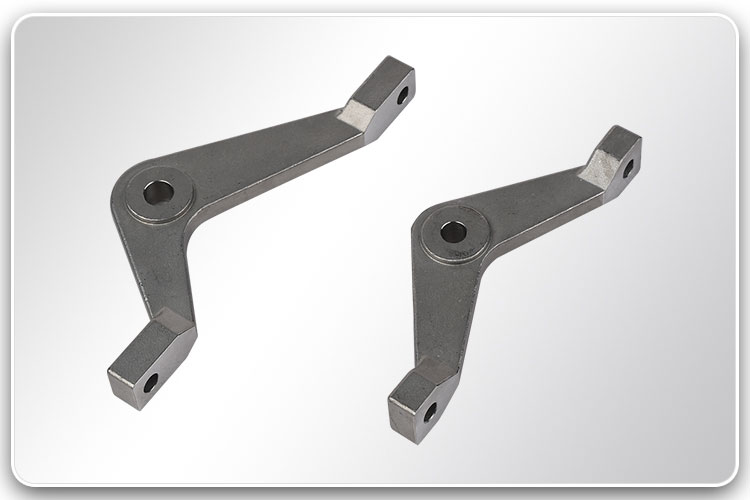

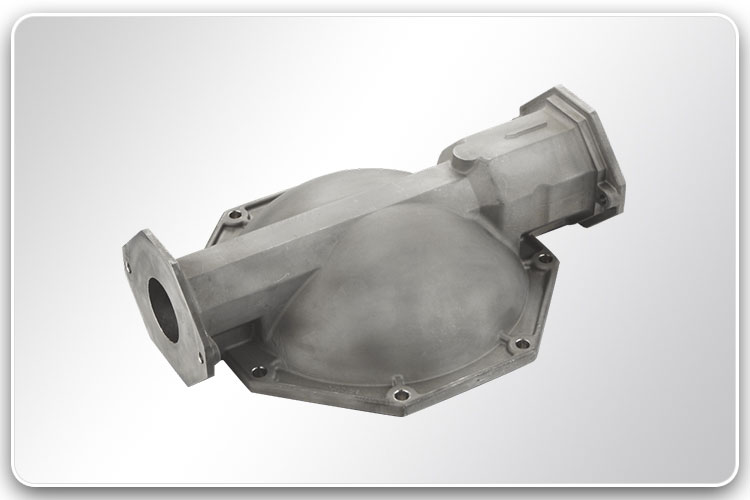

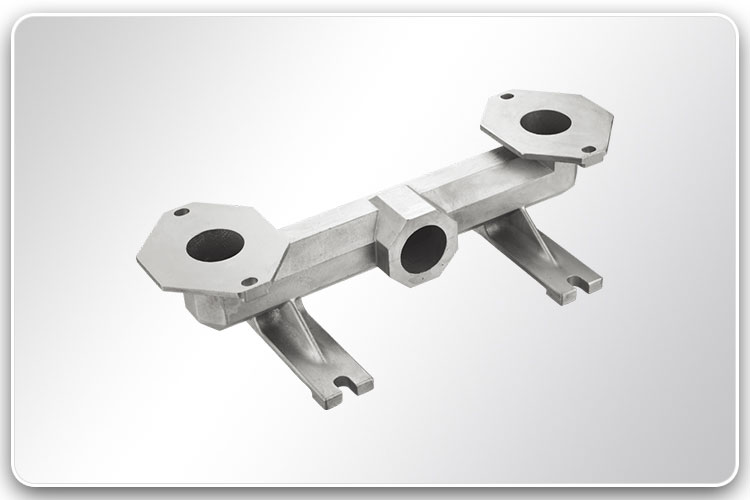

Auwell je pred 15 leti začel razvijati izdelke za ulivanje dupleksa iz nerjavečega jekla 1,44462 za podjetje Germanclient za bazen. Po ulivanju smo izdelali tudi obdelavo v skladu z risbo za naročnika za ta izdelek iz nerjavečega jekla 1.4462 z dupleksom.

Na zahtevo stranki nudimo naslednja poročila za dupleksne ulitke iz nerjavečega jekla 1.4462:

-Chemical components

-Poročilo o preizkusu fizikalnih lastnosti

-Hardness report

-Roughness report

-Metallographic analysis

report

-Poročilo o radiografskem preskusu

-Poročilo o toplotni obdelavi

-Dimenzijsko poročilo

-3D Scanning Report

Auwell konkurenčne prednosti:

-Rich Experience

More than 3 years of

experience in 1.4462 duplex stainless steel casting products development and production, especially to the European markets, with

solid understanding of the material, technical and quality standards.

-Hiter preobrat

Na splošno nudimo aquotation v 3 delovnih dneh. Z združitvijo najnovejših proizvodnih tehnologij in naprav lahko Auwell v preprostih projektih v 3 tednih zagotovi hitre prototipe.

-Celovit ponudnik rešitev

Auwell provides

comprehensive services for 1.4462 duplex stainless steel casting product starting from designing, through prototyping, tooling/fixture

development, sampling, mass production, and to logistic and post-sale support.

-Toge politike nadzora kakovosti

The most rigorous quality

policy starts from material control, and is followed through to final

pre-shipment inspection to 1.4462 duplex stainless steel casting orders. Material certificates include the mill certificate, 3rd party chemical

components, and mechanical property reports, as well as RoHS and REACH reports

upon request. Other reports include dimensional reports, surface treatment

thickness, and salt fog test reports, etc. We structure our processes, creating

Flow Charts and Control Plans before production, making sure all QC processes are

in accordance with ISO9001-2015 requirements and drawing specifications.

-Prilagodljiv rok plačila

Plačila za orodje morajo biti predplačana za razvoj izdelka za ulivanje iz nerjavečega jekla v višini 1,4462. Za množično proizvodnjo ponujamo prilagodljive plačilne pogoje, dobili bomo razumne kreditne pogoje, stranka plača le, če je zadovoljna z izdelkom, ki ga je prejela. Za dolgoročne projekte ponujamo storitve odpoklicnega inventarja za zahteve glede hitre dostave.

Hot Tags: 1.4462 Dvostransko litje iz nerjavečega jekla, proizvajalci, dobavitelji, tovarna, po meri, izdelano na Kitajskem, Kitajska

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик